Frame

|

| Some parts are symmetrical, and

they can be duplicated in resin, but some parts are

not. I started with those asymmetric parts, that doesn't need to be resin cast. |

|

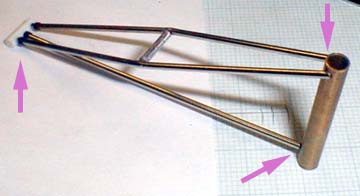

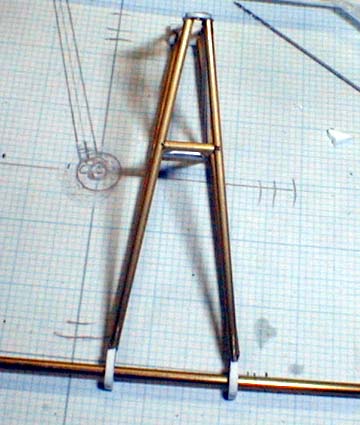

2-1

|

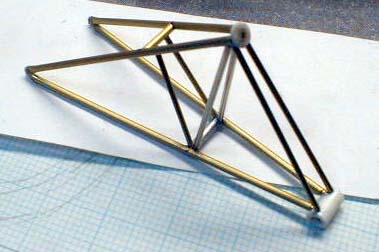

The frame was made with metal rods

of various diameters. I used 0.7 mm pipe for the main pipes, and

0.5 mm and smaller brass rods for the support members.

|

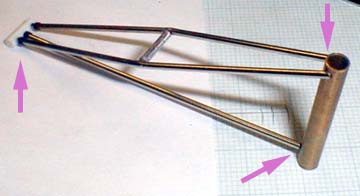

2-2

|

First, I drilled holes on the

front and rear pipes, and I installed small rods for reinforcement. Then, I cut a vinyl pipe and

put them around the end of the three main pipes, which

simulates the bush(?) at the end (3 black pieces near the rear horizontal pipe),

and I added the bridge in the middle of two upper pipes. |

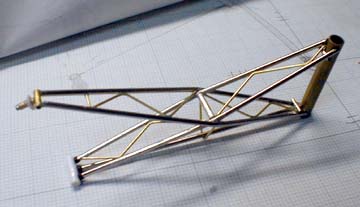

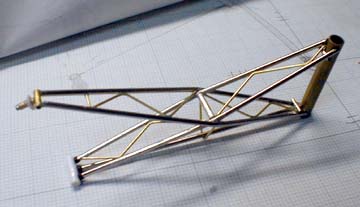

2-3

|

I added support members one by

one, based on the measurement and my drawing.

Here is a picture of the finished

front frame. Small support members were fixed with superglue.

The frame looked good, but this frame wasn't used, because it was too wide after I

put two outer pipes. |

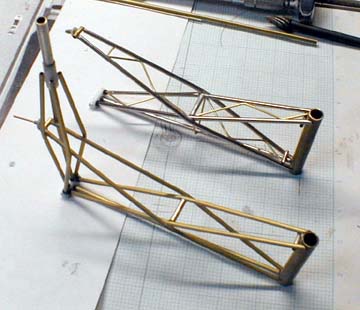

2-4

|

Human eyes don't recognize two

identical objects in different sizes the same way, and that's the tricky part of

modeling. A model has to look better in small scale, instead of

trying to accurately copy it based on the measurements. So, I used 0.6 mm for the main pipes, and 0.4 or smaller for the

support members to make a new frame. This 0.1 mm difference in pipe

diameter made a noticeable difference in 1/8 scale model.

|

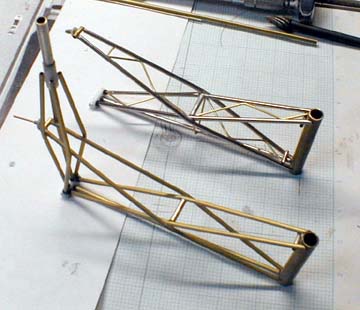

2-5

|

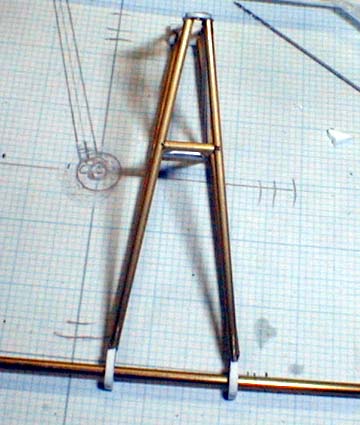

The rear frame was made in the

same manner. The main frame was superglued to the front horizontal pipe, using

some reinforcement pins inside, and the rest was simply superglued. |

2-6

|

This photo shows the frame, which

is almost finished. Some small members had still be installed, and they were

mainly made with 0.5 mm brass rod. |

2-7

|

The end of the rear frame, which

holds the rear axis (what do you call it anyway?) was made from a laminar

plastic sheet.

I drew the shape on a plastic sheet, and I roughly trimmed it to the final

shape. Then, I drilled a hole, inserted a rod, and filed it to

the final shape, while holding two pieces together to make two identical

pieces. |

2-8

|

The center line of the frame and

the rear axis had to be perpendicular to each other. I used a grid

paper to align them correctly. |

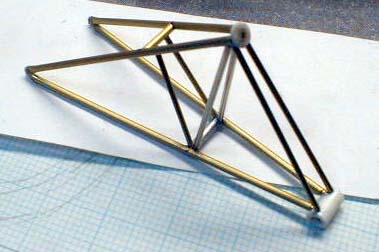

2-9

|

I wasn't sure if super glue was

strong enough to hold the bond, so I soldered the spots, where stress

was expected. The top arrow points at an unfinished spot, while the

bottom arrow shows the sanded and finished spot. The finished frame is shown in the

picture below. |

2-10

|

|

| Next is the rims and

spokes,

and I'll demonstrate how to scratchbuild the rim with plastic sheet. |