|

|||||||||||||||||||||||||||||||

McLaren

Honda MP4/6 |

|||||||||||||||||||||||||||||||

The first thing after easing the tension was to fit the cowl to

the chassis, and reshape the body. Then, superglue was used to fix the loose part

temporarily. Coarse sand paper was used to smooth the gap before applying thinned

putty. The first thing after easing the tension was to fit the cowl to

the chassis, and reshape the body. Then, superglue was used to fix the loose part

temporarily. Coarse sand paper was used to smooth the gap before applying thinned

putty. |

|||||||||||||||||||||||||||||||

The back

of the cowl was sanded a little to eliminate the interference. The gap was filled

with superglue. Notice that I used many different materials and kit parts to form

the part. The back

of the cowl was sanded a little to eliminate the interference. The gap was filled

with superglue. Notice that I used many different materials and kit parts to form

the part.

|

|||||||||||||||||||||||||||||||

Thinned

putty is quite handy because it flows into the gap itself, and conforms to the surface and

flattens itself. I've been using this technique to eliminate the medium sized gaps.

Gunze Sangyo's Mr. Surfacer was inspired by this technique used by the experienced

modelers. Thinned

putty is quite handy because it flows into the gap itself, and conforms to the surface and

flattens itself. I've been using this technique to eliminate the medium sized gaps.

Gunze Sangyo's Mr. Surfacer was inspired by this technique used by the experienced

modelers. |

|||||||||||||||||||||||||||||||

Thinned putty was applied to the necessary areas. It

shrinks a little, but it dries fast. After this, a little finer sand paper was used

to smooth the surface. The gaps can't be eliminated by only once of putty

application, so the same procedure has to be repeated several times. Thinned putty was applied to the necessary areas. It

shrinks a little, but it dries fast. After this, a little finer sand paper was used

to smooth the surface. The gaps can't be eliminated by only once of putty

application, so the same procedure has to be repeated several times. |

|||||||||||||||||||||||||||||||

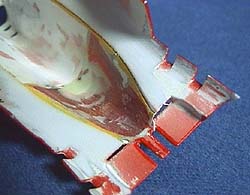

Finally the gaps are getting less noticeable, and they are almost

invisible in the picture. Finally the gaps are getting less noticeable, and they are almost

invisible in the picture.

|

|||||||||||||||||||||||||||||||

The same stage is shown from the back. The left side needs

a little more filling and sanding, but things are going well. The same stage is shown from the back. The left side needs

a little more filling and sanding, but things are going well.

|

|||||||||||||||||||||||||||||||

| Questions and comments? Send mail to Hiroaki Fukuda |

|||||||||||||||||||||||||||||||

McLaren

Honda MP4/6 |

|||||||||||||||||||||||||||||||