|

||||||||||||||||||||||||||||||||

Ferrari

333SP |

||||||||||||||||||||||||||||||||

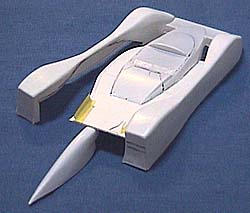

Because the body of the MP4/6 was cracked after painting, I decided to resin cast the master to make the material uniform. First step is to make the master with balsa wood. To make the vacuum forming easy, I separated the body into four components, and I made separate windshield and induction pod also. |

||||||||||||||||||||||||||||||||

To make the side body symmetric, I made a template, and a balsa wood was trimmed using the template to make symmetrical side body parts. The induction pod was also made by using a template. The template was made by tracing the original sketch, and then it was sandwiched by blocks of balsa wood. Then, the unnecessary part was trimmed away. |

||||||||||||||||||||||||||||||||

All major components were already done, so the next step is to vacuum form the body parts. |

||||||||||||||||||||||||||||||||

Number of articles on making a vacuum forming system and how to

make use of it has been published already, so I omit the part. Number of articles on making a vacuum forming system and how to

make use of it has been published already, so I omit the part.The body parts were vacuum formed in four sections, and the intake pod, and the parts on both sides are vacuum formed in two layers. The reason why I add another layer of plastic was to eliminate the texture of the wood and to minimize the deformation later*, and create the extended surfaces that goes under the other parts along the panel lines. (I wonder if this makes sense...) *When two sheets of plastic are glued together, multiple layer helps

minimizing the shear deformation

compared to a single layer plastic sheet. |

||||||||||||||||||||||||||||||||

The rear part and the sloped areas

besides the cockpit were made with plastic sheet,

and it was glued to the center part. The NACA duct, and the brake pod areas are

clipped. Also the inner area of the side parts were trimmed so that it would conform

the slope of the center part. The intake part hadn't been trimmed at that point. The rear part and the sloped areas

besides the cockpit were made with plastic sheet,

and it was glued to the center part. The NACA duct, and the brake pod areas are

clipped. Also the inner area of the side parts were trimmed so that it would conform

the slope of the center part. The intake part hadn't been trimmed at that point. |

||||||||||||||||||||||||||||||||

Ferrari

333SP |

||||||||||||||||||||||||||||||||