|

|

|

Kosan-Kun No1 Hardware Information |

|

|

|

Kosan-Kun No2 Hardware Information |

|

|

|

| |

|

|

| |

|

Casing - Cutting and alumite |

The head is acrylic. The frame making up the

body is aluminum. Basically, it is an original

product cut by myself, but some parts that are

outsourced cutting are mixed.

In the body, the exterior made with resin and

acrylic on aluminum are attached. |

|

|

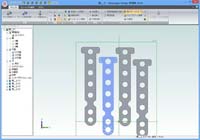

Create drawings of parts with CAD

software. (Drawing

of Kosan-kun No. 1)

Although it is possible to create

three-dimensional parts as long as they

can be seen without obstruction, in the

ordinary cutting, I create a plan view.

As the weight gets bigger, the movement

of the robot gets worse. So, I try to

reduce weight as much as possible. For

example, devise a way to preserve a

certain degree of strength and cutout

some parts.

See Production of CAD

data and aluminum cutting by CNC. |

|

|

I will put the

parts designed by CAD on a cutting

machine called CNC.

The left picture is CNC called BLACK II.

You can puncture the screw hole to the

correct position.

Although aluminum plate is sold at DIY

shops, strength is weak, so I recommend

purchasing from robot parts specialty

store.

Cutting the aluminum with a drill and

cut out the parts takes time. Even small

parts can take several hours to cut.

If you do not have CNC, you can order

aluminum cutting service at a store

selling hobby robot parts etc. If you

send CAD data such as DXF format, the

shop cuts the aluminum and sends it

back.

When purchasing CNC, the point is how

wide you can cut. For example, if the

largest cutting surface is 20 cm × 15

cm, the size of the largest parts that

can be produced will also be this size.

See Production of CAD

data and aluminum cutting by CNC. |

|

|

Since

bare aluminum does not look good, attach

the exterior made with acrylic or resin

to the portion to the blank

spaces. I design parts with 3D software

for 3D printers. Unlike CNC, 3D printers

can create complicated stereoscopic

solids that can not be seen through.

As with CNC, when purchasing 3D

printers, it is the point that how wide

it can produce. The left is a low price

3D printer called Da Vinci. |

|

|

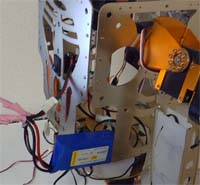

Cutting

aluminum results the color of metal as

it is. It does not look good, so I will

process coloring called alumite. You can

paint parts with ordinary paint, but it

will be bald a little. Since alumite

performs chemical processing, it seems

that the color of the material itself.

Unlike ordinary painting, alumite has

limitations on the color that can be

selected. Particular attention should be

paid to white. White alumite can not be

made because there is no dye. When

placing orders by saying "white" or

"white" to the trader, things that are

transparently alumite return. The right

picture robot uses parts alumite to

green and orange. It is common for

metallic texture to remain even after

alumite.

A kit for selling alumite at home is

sold, but you can also order from an

agency. You can look for places where

you can order a small number of parts of

alumite on the net. |

|

|

|

| |

|

Assembly |

|

Combine the cut aluminum and acrylic to assemble

the robot. |

|

|

Bend

aluminum parts as needed. It is almost

always bent to 90 degrees.

Machines for bending aluminum are very

primitive. It is a feeling that bends a

little by sandwiching an aluminum plate

in a machine. |

|

|

There are

also tools for bending small parts. It

is a product called a pocket vendor.

I think that you can imagine how it

works from the photograph. We hold the

parts and bend it manually with the two

tools. |

|

|

Screw each

part with screws. In hobby robots

appearing in battle tournaments etc., in

many cases screws are used called M2.

Many things around this servo motor are

of this size.

Since there is a possibility that the

screw will break if there is not enough

strength, we choose the one that is as

strong as possible. |

|

|

|

| |

|

Controller (control board) |

Kosan-kun's servomotors

are basically made by Kondo Science.

There are two types of controllers: serial type

and PWM type. Kosan-kun No. 1 is PWM type,

Kosan-kun No 2 is serial type. |

|

|

PWM is a

device type that is also used for PC FAN

controller.

Probably, it is operated by the

frequency of the signal output from the

signal line.

In the case of PWM type, each servomotor

must be wired to the controller.

There is a disadvantage that wiring is

messed up.

The left is the controller around

Kosan-kun No. 1.

There are 24 servos and cables, so I

summarize with tubes. |

|

|

In the

case of the serial type, it is possible

to daisy-chain the servo motors.

The left is the controller around

Kosan-kun No 2.

Since the controller only has cables for

only head, right hand, left hand, right

foot, and left foot, the wiring is

clearer. |

|

|

The green

area is the back side of the controller.

Touching the metal or wetting with water

will cause serious damages. |

|

|

|

| |

|

Actuator |

|

Kosan-kun's servomotor is basically

made by Kondo Science.

Unlike a normal motor (called DC motor), the

servomotor can stop at any specified angle. As

DC motor supplied power, it continues to turn.

The servomotor stops at the angle specified by

the signal line and tries to stay at that angle

even if external force is applied.

As with the controller, there are two types of

servo motors, serial type and PWM type.

Kosan-kun No. 1 is PWM type, Kosan-kun No. 2 is

serial type. |

|

|

PWM type

servo motors include 4024, 4013, 4014,

etc.

(As these products are made with the same size, you can easily replace

each other later.)

The point of which servo motor to be

used is torque. If the torque is weak it

will make it difficult to get up and

walking.

Although 4024 is inexpensive, the torque

is weak and the internal gear is also

made of resin, so it will crack

immediately.

4014 is high torque. The torque of 4013

is slightly lower, but the speed is

faster. Kosan-kun No.1 applies in

combination with 4014 and 4013. |

|

|

There are

4031, 4032, 4033, 4034, etc. for serial

type servo motors.

4031 is inexpensive and weak torque.

4034 has a high torque, 4033, 4032 a

torque is dropped and the speed is

faster.

Kosan-kun No. 2 is made up of

combinations of 4032, 4033, and 4034. |

|

|

|

| |

|

Power supply unit |

|

|

|

|

Voltages of parts that are generally

distributed include 5 V, 7 V, 12 V, etc.

5 V is the USB voltage. 7V is the

voltage used for radio controllers and

so on. 12V is the voltage of the car's

battery. Cigar socket etc is also 12V.

Since the internal voltage of the PC is

also 12 V, parts such as hard disk and

FAN operate with 12 V in many cases.

Servo motors and controllers are

available in 7V or 12V.

Both Kosan-kun No. 1 and 2 are powered

by 12V.

If it is set to 12V, it is convenient

because parts sold as accessories for

cars such as LEDs and parts of the

personal computer can be diverted as it

is.

The left blue pack is the battery. |

|

|

In order

to see the state of the battery, the

front of the robot is equipped with an

LED counter that displays bolts.

Values between 11V and 12V are

displayed. Although it should not

operate when the voltage is low,

depending on the battery, even if the

value is as low as 8 V, it seems that it

can supply the necessary power to work

properly. (It seems that it is not a

simple thing when the voltage drops to

11 V. In some cases it may work and some

cases it may not work.)

|

|

|

NiCad and LiPo

(Lithium polymer) etc are available for

a battery for robot.

Capacity is indicated in milliamps.

I want at least 800 mA. Still it can

only drive about 5 minutes. (It depends

on usage.)

I have a maximum of 2,500 mA, but it

costs more than 10,000 yen.

For charging, a charger for LiPo is

necessary. It usually comes with a

function called a balancer, in addition

to + -, a balancer terminal is attached.

Lithium polymer

requires careful handling.

|

|

|

When a 100

V outlet can be used, it can be used for

power supply by converting to 12 V using

stabilized power supply.

Since the power unit of the PC is also

12V, it should be usable.

The left is a regulated power supply.

Using the stabilized power supply may

cause the remote control to become

ineffective. Probably, I think that

noise is contained when moving the servo

motors at once. The stabilized power

supply has a knob that corresponds to

noise, and it seems that trouble

decreases when adjusting this, but it is

not certain. Troubles of remote control

do not occur with battery for robot. I

think that trouble of this remote

control is related to the instantaneous

power of the battery described later,

but it is not certain. |

|

|

For a car

battery, a cheap one can be bought for

about 2500 yen at Amazon.

It is a type with liquid inside, the

battery for the car is 12V, the battery

for the motor cycle is 6V.

When purchasing, since only the battery

is contained in the box, I purchase the

terminal parts for installation at the

DIY shops. It is about 500 yen. (I think

that you can connect even if you do not

have a terminal ...)

Since capacity is larger, it can be used

for outdoor events without power supply.

Unlike using with car, after using it,

you have to charge, so you need a

charger for the car's battery.

The size of the battery for the car can

be known from the model number, but the

capacity (ampere) is not clear. You can

check the capacity from the model number

on the net. |

|

|

The

performance of the battery is roughly

determined by the number of volts and

ampere, but besides that, there is

performance like an instantaneous power.

From the experience, if the

instantaneous power is low, when turning

on the robot (when the servos move all

together?), it seems that there is a

case where resetting is applied without

power and then it does not work well

after that.

It will happen if the batteries for the

robot are exhausted. I think that this

tends to occur, compare to using an

on-board battery.

This battery for radio control car, the

value of this instantaneous power may be

indicated in the package. (I forgot the

name of the unit, probably the value of

CCA or RC.) |

|

|

|

| |

|

|

| |

|

|

|

| |