Hardwood Power Generation

Greenwood

|

Hardwood Power GenerationGreenwood |

Introduction

After the World War II, Japanese government asked forest owners to cut natural hard wood forest and plant softwood like cedar (a cryptomeria). Because cedar grows faster than hard wood and may help reconstruction of houses. But soon, builders found imported logs and chips are more cost competitive. As a consequence, forest owners lost interest in this business and now most of the Japanese forest are left aside and accumulating wood resources. It looks like a rain forest now. Japan is now importing 85% of chips now mainly from North America. But Japanese forest owner continued using hand held engine saw for felling and they could not use powerful grappel skidder for taking log out of the forest. Some times, helicopter is used. There are two reasons of not using big machinery. Firstly, steep terrain, secondly, fragmented ownership of the land. On the other side of Pacific Ocean, Forest machinery like feller buncher, harvester, grappel skidder are commonly used. Ironically, base machines are earthmoving machines like excavators exported from Japan.

I have made a cash flow analysis of forestry business using commonly used forest machinery in Japanese forest and found very competitive. My study assumes sustainable level of felling assuming natural growth rate of 3.2 green ton / ha/ year. This figure is a very conservative figure of hard wood. I actually confirmed this figure personally by reviewing aerial photos taken periodically over 50 years of the forest just behind my house. Normally 10 green ton /ha/ year is reported in US and in Australia. But those are the figures of fast growing wood. To overcome obstacles of fragmented owner ship, I am proposing a kind of trust organization sponsored by local government. For overcoming harsh terrain, our machinery industry in Japan is eager to help at any time.

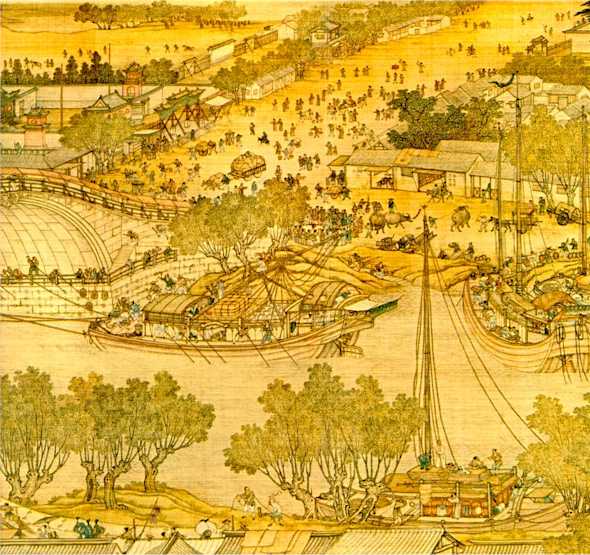

Soft wood like cedar needs plantation after deforestation. But a hardwood sprouts after cutting trunk. Utilizing this characteristics, hardwood could be used as energy plant. I had seen many such trees in Spain and Portuguese. Such trees could be seen in Color and ink on Silk 35.6cm x 1152.8cm Handscroll painting of Ch'ing-ming Festival on the river depicting life in the capital of K'ai-feng of Sung dynasty.

a part of color and ink on Silk 35.6cm x 1152.8cm Handscroll painting of Ch'ing-ming Festival on the river

Hardwood forest has superior characteristic than soft wood forest for preserving water resources and protection of steep terrain.

Business Model

The business model is to lease land from the owner who lost interest in forestry business and introduce forest machinery for felling. Felling interval would be 20 or 40 years. Total land area shall be sufficient for sustainable recovery of the logs after felling. Felled logs are taken out of the forest by skidding and chipping. Feller and skidder is suported by tender for safety in steep terrain. Collected chips may be transported to power generation plant by trucks. Gasturbine simple cycle may be selected for low investment type power generation system.

conceptual drawing of the business model

Feeding dry chip of 1.8dry ton/h (water content of 20wt.%) to power generation plant was taken as study base. If the plant operate 320 days in a year and chip yeald is 97.1%, annual felling volume will be 22,779green ton/year (water content of 50wt.%)

It was assumed that growth rate of hardwood forest is 3.2green ton/ha/year. This is a very conservative figures.

Two case study was made for 20 and 40 years felling cycled and found 40 years cycle is economical for forest machinery productivity. When 40 years cycle is adopted, breadth height diameter of the wood be 30cm, and tree weight is 0.53 green ton. When 20 years cycle is adopted, breadth height diameter of the wood be 21cm, and tree weight is 0.26 green ton.

hard wood forest after 40 years

Based on those base, lease cost of the land and annual felleing area become as below.

| Items | Unit | 40 years interval | 20 years interval |

| Annual felling volume | green ton/year | 22,779 | 22,779 |

| Area required for sustainability based on annual growth rate of 3.2 green ton/ha/year | ha | 7,118 | 7,118 |

| Land value: 300,000 yen/ha | million yen | 2,136 | 2,136 |

| Lease cost equivalent to property tax of 1.4% | million yen/year | 29.9 | 29.9 |

| Felling cycle | years | 40 | 20 |

| Forest Density | green ton/ha | 128 | 64 |

| Annual felling area | ha | 178 | 356 |

| Number of stems in 1 hectare | stems/ha | 241 | 246 |

| Annual operating days | d/year | 320 | 320 |

| Felling number of stems in a day | stems | 134 | 274 |

Specification of Forest Machinery

Productivity data of forestry machinery by T.P. McDonald et.al., USDA Forest Service were used for the basis of cost study. It was assumed that initial investment for moderate terrain in Japan is 20% and for steep terrain 100% higher than that of the figure in 1993.

In case of 40 years cycle, 1 machine each for felling and skidding is considered adequate. But in case of 20 years cycle, 2 machines might be required. Therefore, 40 years cycle seems most economical scehme for natural hardwood forest.

Total number of operator for 41 years cycle were taken as 4 person.

| Items | Unit | Felling | Skidding | Chipping |

| Type of machinery | - | Feller Buncher | Grappel Skidder | Chipper |

| Catalog number | - | HydroAx 411 | Tinmerjack 450B | Morbark Model 30 |

| Looks like | - |  |

|

|

| Annual capacity | green ton/year |

22,779 | 22,779 | 22,779 |

| Operationg days | d/year | 320 | 320 | 320 |

| SMH | h/d | 6 | 6 | 6 |

| Productivity | % of SMH | 65 | 60 | 75 |

| PMH=SMH*Productivity | hr | 3.9 | 3.6 | 4.5 |

| Felling time per PMH @ 40 year cycle | min | 1.7 | - | - |

| Felling time per PMH @ 20 year cycle | min | 0.8 | - | - |

| Duty per PHM | green ton/SMH | 18.3 | 19.8 | 15.8 |

| Capacity of a machine | green ton/SMH | 18.5 | 24.6 | 57 |

| Number of machine | - | 1 | 1 | 1 |

| Engine nominal power | kW | 94 | 132 | 600 |

| Fuel consumption rate | liter/kWh | 0.13 | 0.14 | 0.12 |

| Fuel cost(80yen/liter) | million yen/year | 1.88 | 2.84 | 11.06 |

| L.O cost:37% of fuel cost | million yen/year | 0.69 | 1.05 | 4.09 |

| Insurance | million yen/year | 0.68 | 0.73 | 0.69 |

| maintenance | million yen/year | 0.88 | 0.77 | 2.04 |

| Number of operator | persons | 1 |

1 |

1 |

| Initial Investment for moderate terrain | million yen | 15 | 14.5 | 34.7 |

| Initial Investment for steep terrain | million yen | 25 | 24 | 34.7 |

SMH: Scheduled Machine Hour

PMH: Productive Machine Hour

Felling, Skidding and Chipping Cost

Ex-forest chip cost for moderate terrain is 1,948yen/m3. Transportation cost of the chip over 40km distance is 583yen/m3. Total cost of 2,530 yen/m3 is far lower than market price of hardwood chip of 9,300 yen/m3.

| Items | Unit | Moderate Terrain | Steep Terrain |

| Initial investment of forest machinery | million yen | 64.2 | 83.7 |

| Net Cash flow/Initial investment of 9.18% | million yen/year | 5.9 | 7.7 |

| Property tax of machinery: 1.4% of initial investment | million yen/year | 0.9 | 1.2 |

| Administration cost: 1% of initial investment | million yen/year | 0.7 | 0.8 |

| Labor cost (4persons x 6million yen/year/person) | million yen/year | 24 | 24 |

| Fuel Cost | million yen/year | 15.8 | 18.0 |

| Lube oil cost | million yen/year | 5.8 | 6 |

| Insurance | million yen/year | 2.1 | 2.7 |

| Maintenance cost | million yen/year | 3.7 | 4.8 |

| Felling, skidding and chipping cost | million yen/year | 58.8 | 65.2 |

| Land lease | million yen/year | 29.9 | 29.9 |

| Unit chip cost(Sp. Gr.=0.5) | yen/m3 | 1,948 | 2,087 |

Net cash flow/Initial investment of 9.18% is based on the following bases.

| Items | Unit | Figures |

| Capital/Initial Investment ratio | % | 40 |

| Discount rate of net cash flow | % | 8 |

| Project period | years | 30 |

| Depreciation period | years | 17 |

| Depreciation method | - | ?? |

| Income tax rate | % | 40 |

| Interest rate | % | 4 |

| Debt period | years | 10 |

| Debt service | - | Equal installment |

| Salvage value/Initial investment | % | 0 |

Transportation Cost

Transportation by Truck could be out sourced. Unit rate of 30yen/km-ton is 3 time of that of US level.

| Items | Unit | Figures |

| Quantity | green ton/year | 22,118 |

| Transportation distance | km | 40 |

| Annual expense | million yen/year | 27 |

| Unit cost of transportation | ten/m3 | 583 |

Specification of Gasturbine Generator

Instead of conventional BTG (boiler turbine generator), GTG (gasturbine generator) is most suited for wood gasification power generation. The gasturbine burns gas from gassifier operating at 6 atmosphere. Methane rich gas is generated at such high pressure as shown below.

The energy conversion efficiency of the gassifier is 80.9%. When gasturbine is tailor made for wood gas having low HV, gasturbine efficiency can reach 33.6% as excess air rate is lower. 2.43MW power will be generated from 1.8 ton/h dry chips. Diameter of the gassifier is 2 m. The same design program developped for design of Wood Gas Cart was used.

Flow sheet of Gassifier and Gasturbine Generator

Gas Composition at various Operation Temparature

Alternatively, direct burning gasturbine would be feasible.

Direct Burning Gas Turbine

Power Generation Cost

Asuuming the same net cash flow/Initial investment of 9.18%, unit price of power becomes 14.7 yen/kWh.

| Items | Unit | Moderate Terrain | Steep Terrain |

| Initial investment of power plant | million yen | 732 | 732 |

| Net cash flow/Initial investment of 9.18% | million yen/year | 67 | 67 |

| Property tax of the plant: 1.4% of initial investment | million yen/year | 10 | 10 |

| Administration cost: 1% of initial investment | million yen/year | 7 | 7 |

| Insurance: 0.5% of initial investment | million yen/year | 4 | 4 |

| Maintenance cost: 2% of initial investment | million yen/year | 15 | 15 |

| Lube oil cost | million yen/year | 6 | 6 |

| Labor Cost(6operators x 6million yen/year/person) | million yen/year | 36 | 36 |

| Land lease | million yen/year | 29.9 | 29.9 |

| Felling, skidding and chipping cost | million yen/year | 58.8 | 65.2 |

| Transportation cost | million yen/year | 27 | 27 |

| Annual cash flow | million yen/year | 260.1 | 266.6 |

| Unit price of power | yen/kWh | 14.2 | 14.6 |

Additonal cost for steep terrain is only 0.4yen/kWh.

As all wood chips are photosynthetic producrts, the power could be regarded as Pseudo Solar Power. Power cost of 14.7 yen/kWh is feasible if green power credit is applied. For other alternative power cost, please refer to Cost of Various Solar Power.

May 8, 2003

Rev. November 7, 2010